Acetals

What is Acetal?

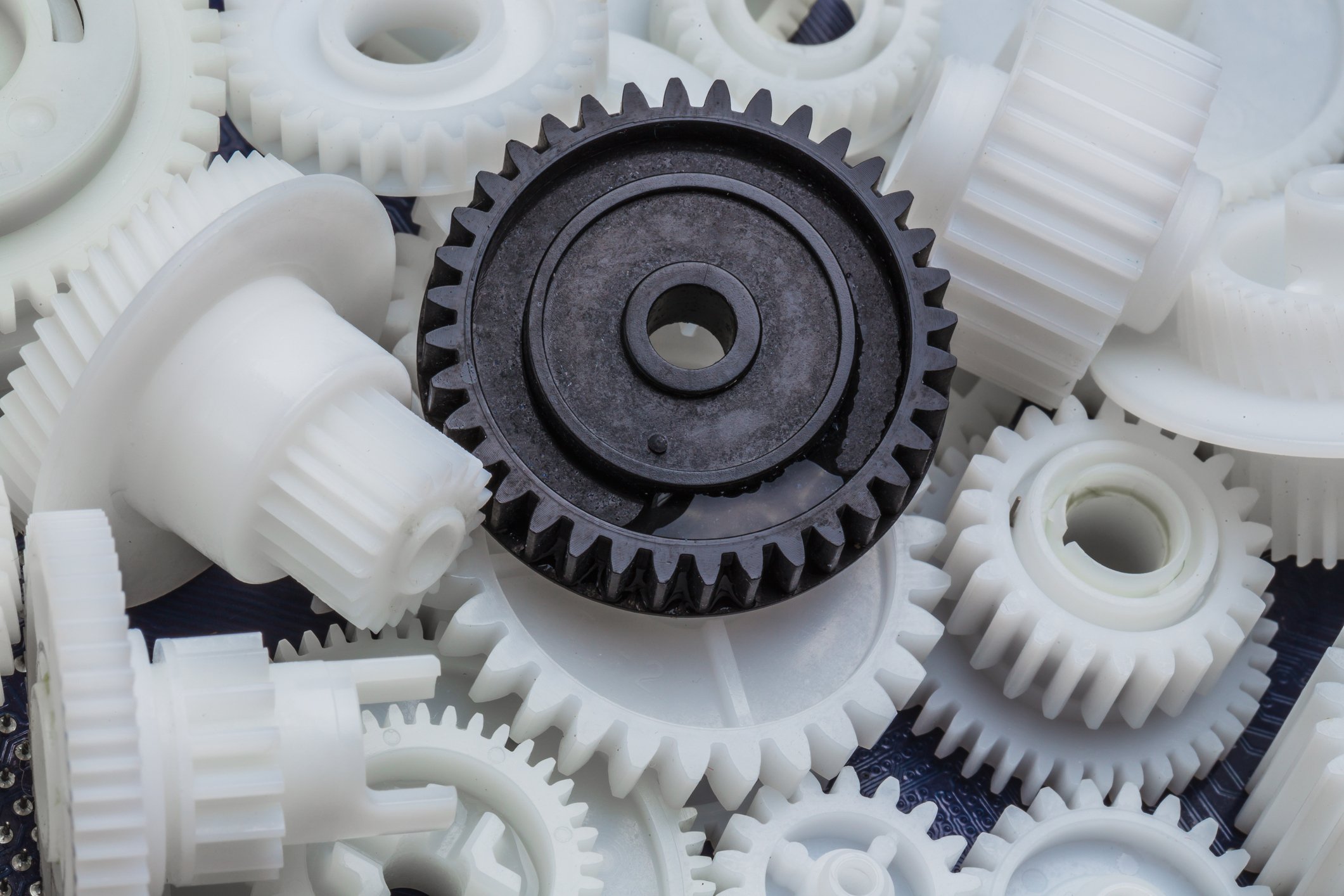

At The Plastic Factory in Bridgeport, Connecticut, we specialize in acetal materials and custom fabrication services. Acetal is a versatile thermoplastic polymer known for its strength, low friction, and wear resistance, making it suitable for a wide range of applications. Our goal is to deliver custom acetal products tailored to the unique requirements of different industries. Acetal provides reliable quality and value for those in need of durable components and flexible manufacturing solutions. Rely on The Plastic Factory for precision-engineered acetal products that enhance your project's performance and longevity.

We offer acetal in both sheets and rods.

Applications of Acetal:

Medical Devices: Components like surgical instruments, dental devices, and diagnostic equipment use acetal for its strength, biocompatibility, and ease of sterilization.

Electrical and Electronics: This material is suitable for electrical connectors, insulators, and housings because of its good dielectric properties and dimensional stability.

Plumbing: Fittings, valves, and manifolds in plumbing applications rely on acetal for its durability, low friction, and resistance to various chemicals and temperatures.

Key Features of Acetal:

High Strength: Acetal is known for its exceptional mechanical strength and stiffness, making it ideal for load-bearing applications.

Low Friction: This material offers excellent low friction properties, ensuring smooth operation in moving parts and reducing wear.

Chemical Resistance: Acetal is resistant to many chemicals, solvents, and fuels, making it suitable for use in harsh environments.

Dimensional Stability: Acetal maintains its shape and dimensions even under varying temperatures and moisture levels, ensuring consistent performance.

Ease of Machining: Acetal is easy to machine and fabricate, allowing for precise and efficient manufacturing processes.

Frequently Asked Questions:

-

Acetal outperforms many other plastics in terms of mechanical strength, stiffness, and dimensional stability. It also offers low friction and excellent wear resistance, making it ideal for applications requiring high precision and durability.

-

Yes, acetal is safe for use in medical devices and food processing equipment. It is biocompatible, easy to sterilize, and compliant with FDA regulations for certain applications, ensuring it meets stringent safety and hygiene standards.

-

Acetal can operate effectively in a wide temperature range, typically from -40°C to 120°C (-40°F to 248°F), making it suitable for both low and high-temperature applications.

-

While acetal offers good resistance to moisture and UV exposure, prolonged outdoor use can lead to some degradation. For long-term outdoor applications, additional UV stabilizers may be recommended.

-

Acetal is renowned for its excellent wear and abrasion resistance, making it ideal for applications involving sliding or rotating parts. Its low friction properties help extend the lifespan of components.